Full-automatic material and bronze needle loading, automatic heat and

automatic temple, all of them are achieved at once and all parts are run with

the screw rod guide rail without personnel supervision and with high

efficiency and good accuracy. The machine can realize the production of

7080 pairs per hour, and one person can watch 10 machines, which greatly

reduce the labor skill, improve the quality and shorten the production cycle

Combined with CNC automatic planing machine, the two sets can complete

the whole process of temple, which is the most ideal and effective helper of

the rubber ratio department

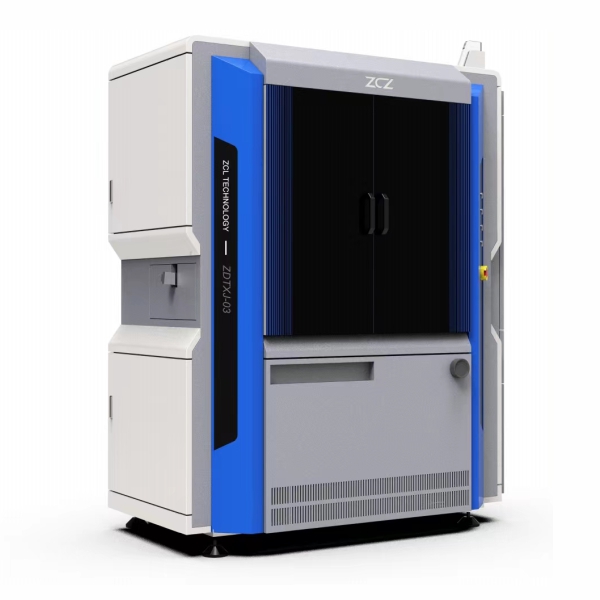

Automatic feeding system

CNC high-precision mechanism

Automatic pin delivery mechanism

SMC pneumatic components, OMRON electric apparatus

Taiwan HIWIN screw and guide rail with original packaging

Automatic temple shooting mechanism

10-ton pressure cylinder

Cooling and circulating system

4 sets of Japan Yaskawa servo motor

Automatic discharging mechanism

Save labor,matters and time

All parts are run with the screw rod guide rail

The precision of temple is over 3 times higher than traditional machine.

Automatic materials and bronze needles loading and discharging

Processed temple is smooth and bright without doing other handwork.

Automatic constant temperature device stably controls all base levels of temple.

The humanized system with simple machine adjusting ensures that the machineis always ready to use

| Performance index | standard value |

| Positional accuracy of X/Y/Z axes movement | 0.015mm |

| The accuracy of repetitive positioning of X/Y/Z/A axes | 0.010mm |

| Temperature | Controlled at 1-degree deviation, 0-300 adjustable, machine power, lathe dimensions |

| Papid movement speed | 30M |

| Machine power | 3.5KW |

| Working voltage | 380V/50HZ |

| Driving system | The full set of original Japanese Yasjawa Servo*4 |

| Operating system | SYNTEC systen +hand box |

| Air pressure | 0.8MPA |

| Machine tool weight | 850KG |

| Machine dimension | 1700*1000*2200mm |

Jion Us ZCL | Yue ICP Bei No.99999999 Copyright 2023 All Rights Reserved By ZCL | 0752 28687538

Pay Attention To Us