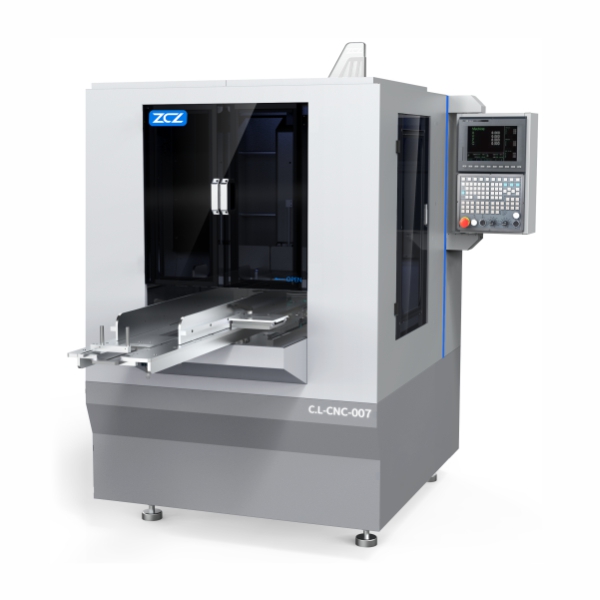

Equipped with 3 sets of machine heads, fully automatic cutting and planing, multiple processes such as milling vertical surfaces, chamfering, slotting, etc. can be completed in one time, saving time, improving efficiency and accuracy. Equipped with automatic sorting and picking temple function, the processed materials are classified and placed in the material tray, and equipped with CCD to automatically identify and cutting materials. It is also the best choice for high-definition material cutting.

Original DELTA servo motor

SYNTEC system +hand box

Temple planning horizontal machine head

Left and right discharging device

Cutting temple vertical head

Automatic loading device

Taiwan HIWIN screw and guide rail with original packaging

It can realize the automatic cutting and temple planning.

It can save labor and moule, safe and reliable.

The precision is high, and the finish is good.

Automatic sorting of left-right temple.

It can be automatic recognition and cutting by CCD image.

| Performance index | standard value |

| Positional accuracy of X/Y/Z axes movement | 0.015mm |

| The accuracy of repetitive positioning of X/Y/Z/A axes | 0.010mm |

| Operating stroke of X/Y/Z axes | 500mm*500mm*200mm |

| Spindle power | 1.5w×2/1.5KW×3 |

| Spindle speed | 1000-24000RMP |

| Spindle number | 20M/MIN |

| Shank mode | ER16 |

| Working voltage | 220V/50HZ |

| Driving system | Delta servo x5 shaft |

| Operating system | SYNTEC system +hand box |

| Air pressure | 0.6MPA |

| Machine tool weight(KG) | 2000KG |

| Machine dimension | 1450*1550*1850mm |

Jion Us ZCL | Yue ICP Bei No.99999999 Copyright 2023 All Rights Reserved By ZCL | 0752 28687538

Pay Attention To Us