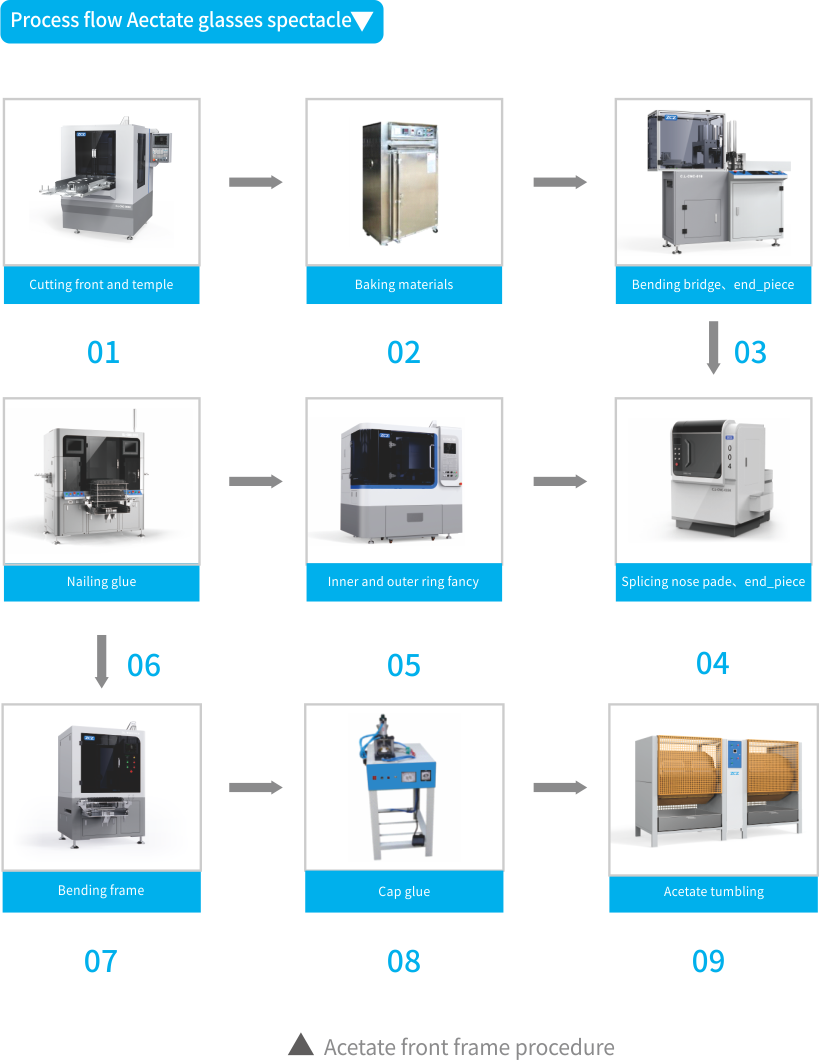

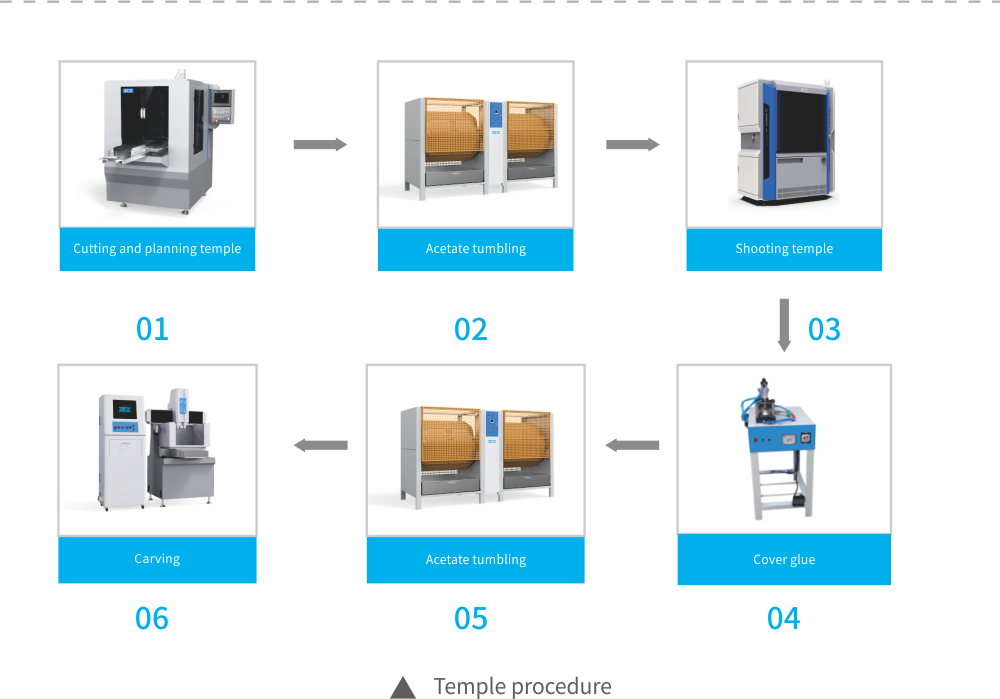

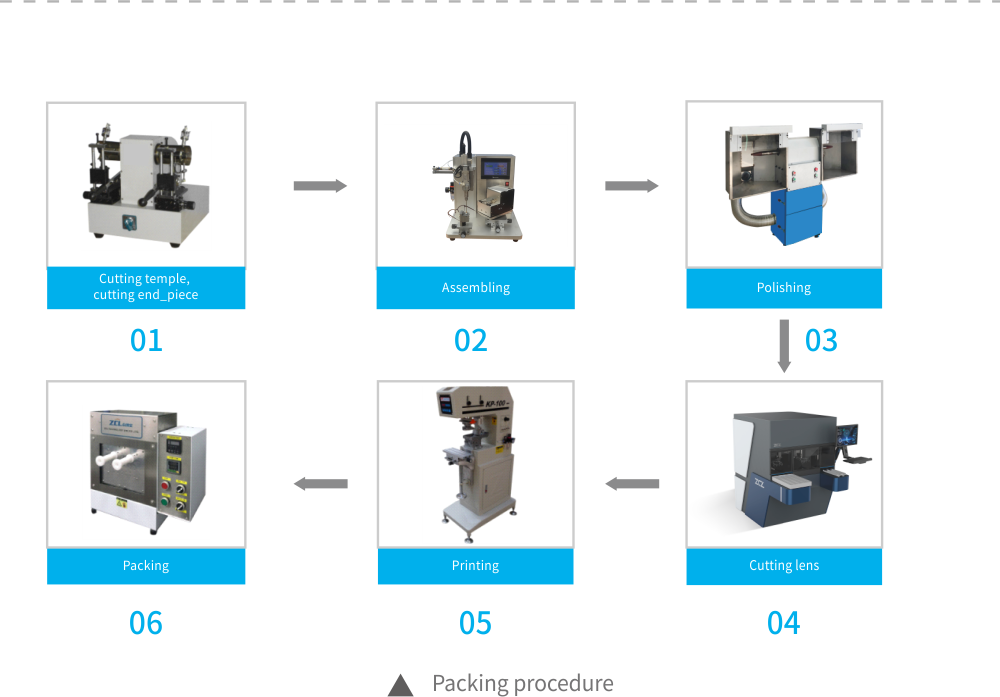

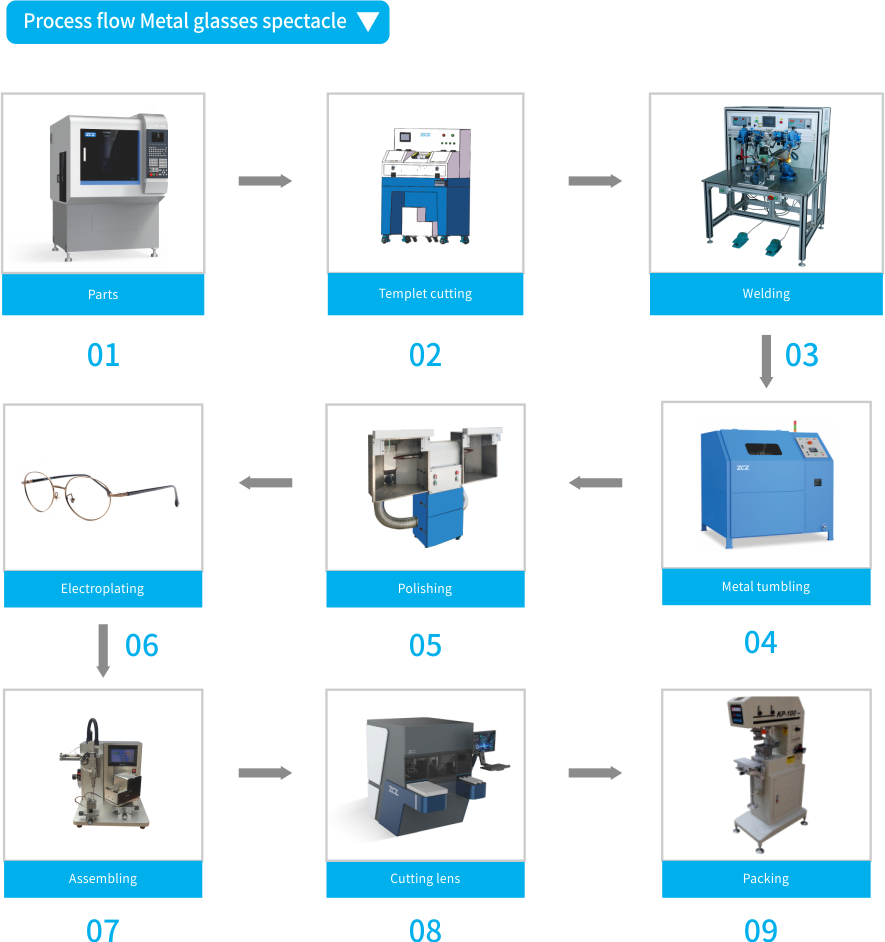

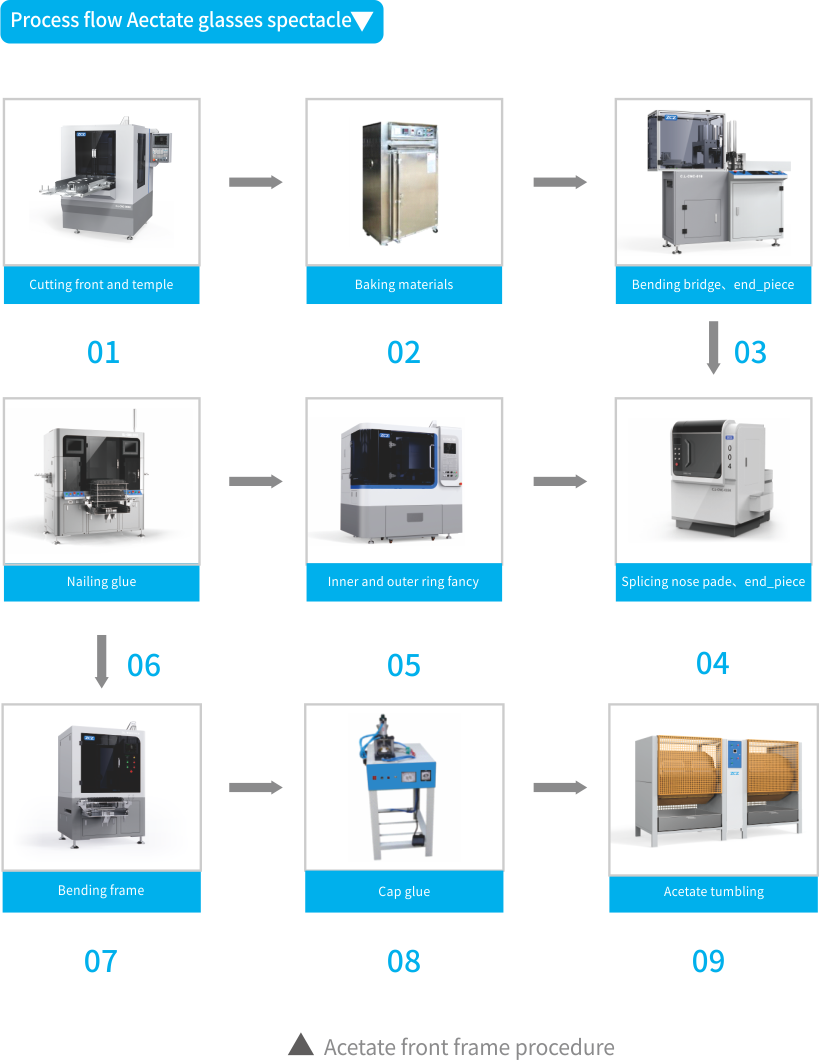

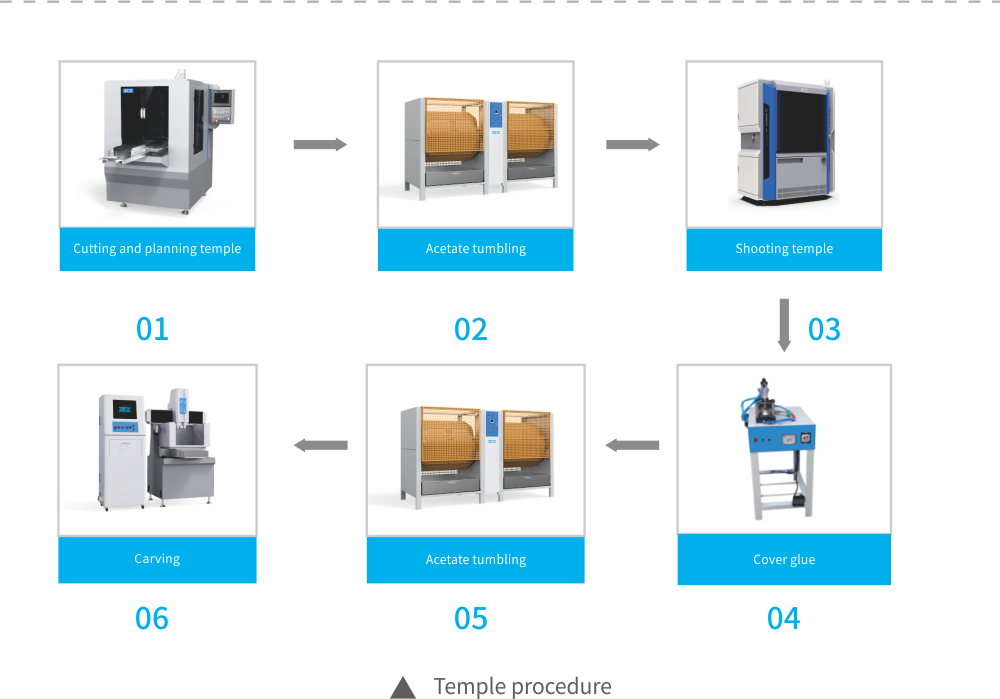

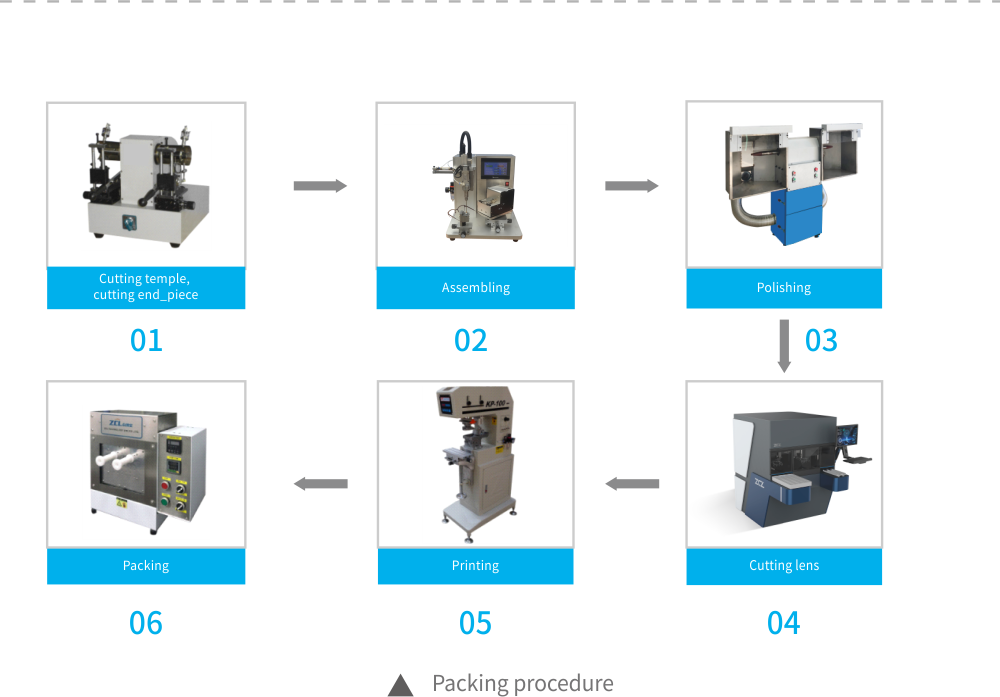

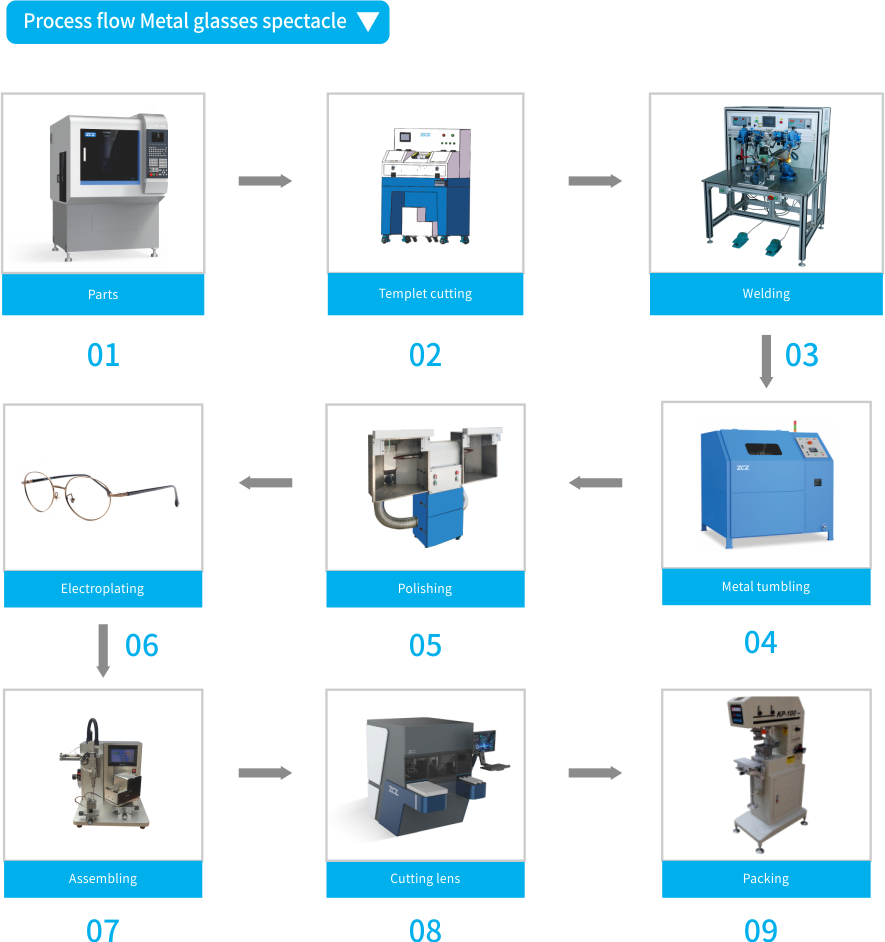

High investment on purchasing equipment to ensure high precision and standardization of production process

Advanced equipment ensures efficient customization and increasing production efficiency

The advanced productive force is originated from the most advanced production equipment. In the vertical industries with segmentation of spectacle manufacturing equipment and part manufacturing and supply, ZCL adopts the heavy-asset operation mode which is unique in the industry and invests more than 10 million Yuan on purchasing hardware, top in the industry. Based on the above, ZCL is capable of ensuring high precision and standardization of part production, in particular to consistency of parts of different batches of the same model to meet modulization and automation of production process and realistic requirements of smart upgrading of the production line.

Drive productivity with full automation

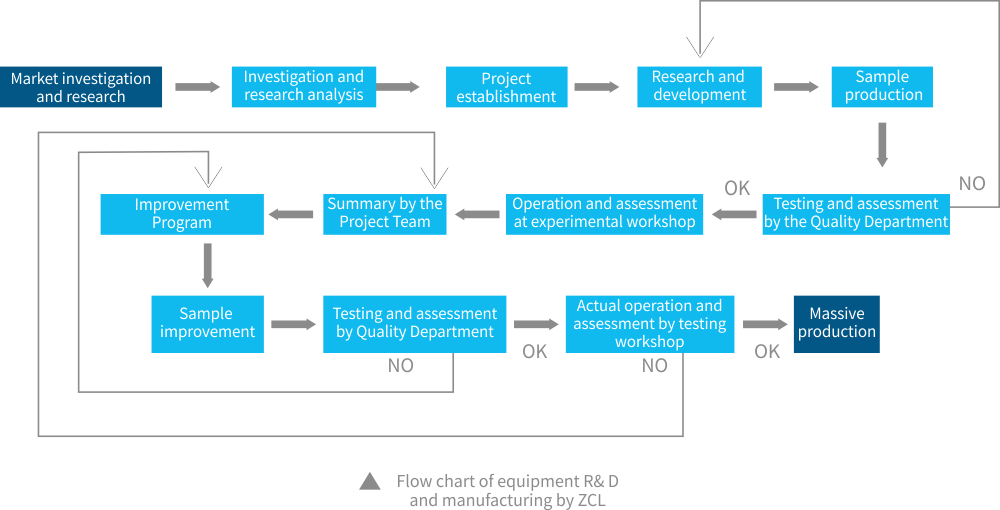

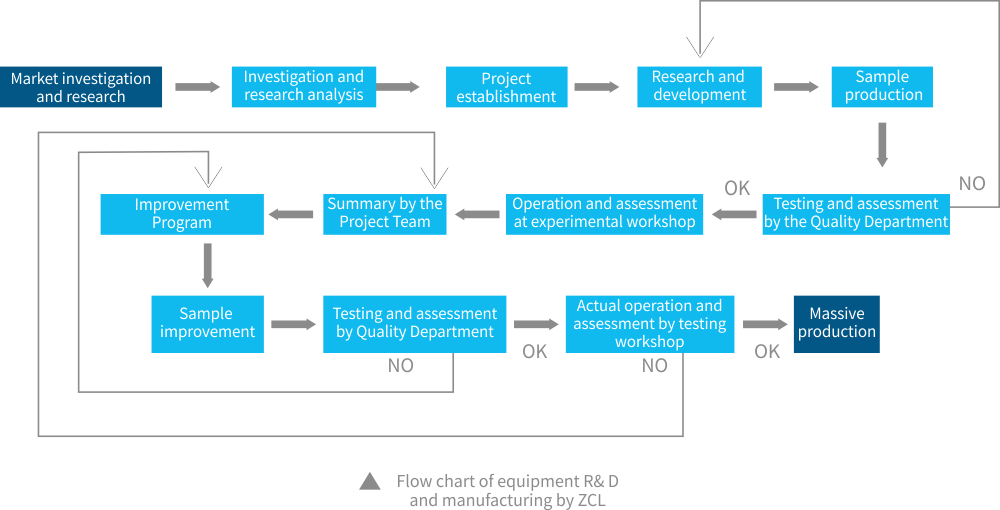

Scientific research and development, adhere apply theory to practice.

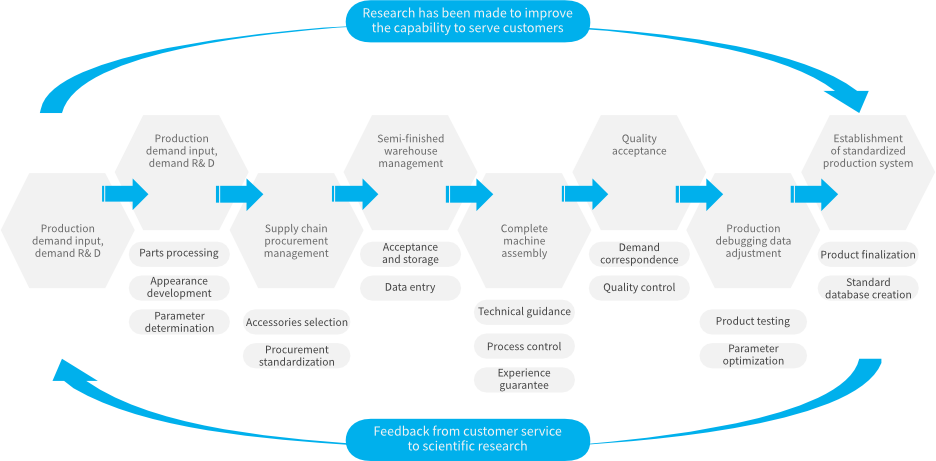

All the scientific research and innovation activities created by ZCL are centered on the technical difficulties and improvement needs of customers in the production process, and the results should also be applied to the production reality. In ZCL, there is a solid two-way promotion mechanism between enhancing technology reserves and enhancing customer service capabilities, which ultimately promotes the transformation of scientific and technological productivity and the iteration of the industry's scientific and technological level.

Efficiently integrating industrial resources

As for receiving orders and production capacity, it optimizes production capacity, supply and demand of the industry

ZCL only does one thing in the past 18 years after foundation, namely specializing in spectacle manufacturing equipment and technology supply. Based on reality of low centralization of spectacle, more industrial chain procedures and frequent change of supply demand, ZCL links orders and production capacity with its identity out of the industrial chain and sensitive industry information, effectively combines resources within the industry and ensures that the orders are finished precisely, on high-quality and timely.

Ensure that the productive capacity is implemented quickly

Before delivery of the machine, customers deliver spectacle drawings or samples to ZCL, which provides spectacles molds required for the supporting equipment, helps customers reduce production time and interfaces production quickly.

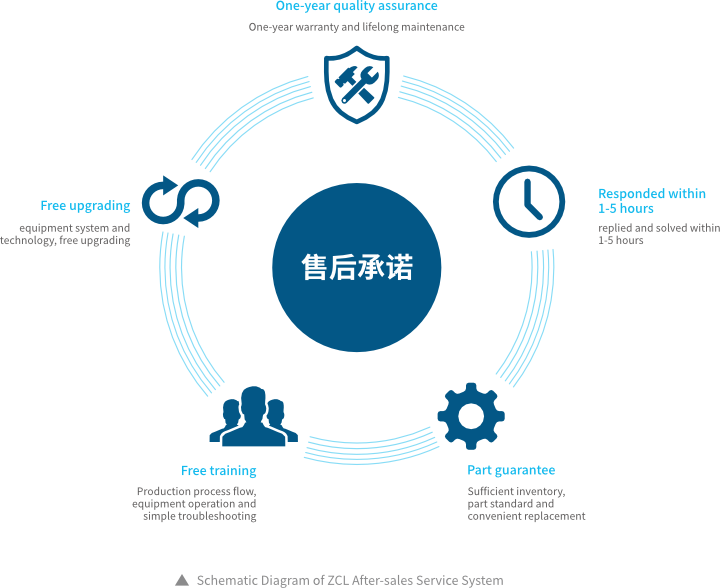

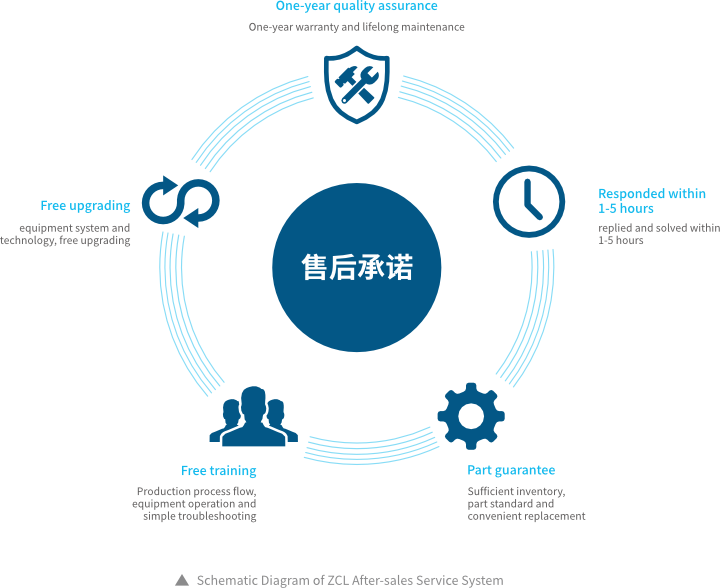

Fast after-sales service to ensure productivity

Customer-centered, bi-directional promotion between customer service and internal R& D

ZCL are a service oriented eyewear production equipment and technology supplier. The company took the lead in the industry to set up a full-time customer department, seamless connecting customer, R & D & Engineering department, to provide customers with flexible and timely, the whole process, covering the global after-sales service. In our after-sales service area, we promises to solve the problems within 24 hours.

The customer department is seamlessly connected with the R&D & Engineering Department. All employees have deep knowledge and practical experience in the R&D and production, maintenance and repair, as well as the manufacturing process of eyewear. They can remove production faults for customer in time and provide timely and reliable equipment commissioning, staff training and other services, and provide better quality eyewear production solutions to ensure the continuous productivity of customers.

Build a "smart factory", iterating industry productivity with intelligence.

“smart factory”, replicable new generation eyewear manufacturing plant.

In line with the high-end transformation of the eyewear manufacturing industry and the good situation of the development of the eyewear manufacturing cluster, ZCL began to implement the "smart factory" plan, aiming to create a new generation of eyewear manufacturing factories that can be directly copied by eyewear manufacturers and significantly improve the production energy efficiency.

The plan is based on scientific research and innovation, the goal is to lead the overall upgrade of the world's eyewear manufacturing production line, focusing on the overall improvement of eyewear manufacturing efficiency. Gradually build and improve the "smart factory"——It covers the seamless connection of four major plates: intelligent production equipment, standardized process flow, intelligent material storage, and intelligent management system. So far, ZCL has fully verified the superiority of "smart factory" in some key chains, and it can be fully carried out in the next three years, providing customers with latest production line and efficiency optimization solutions through the whole chain of "equipment - process - management".