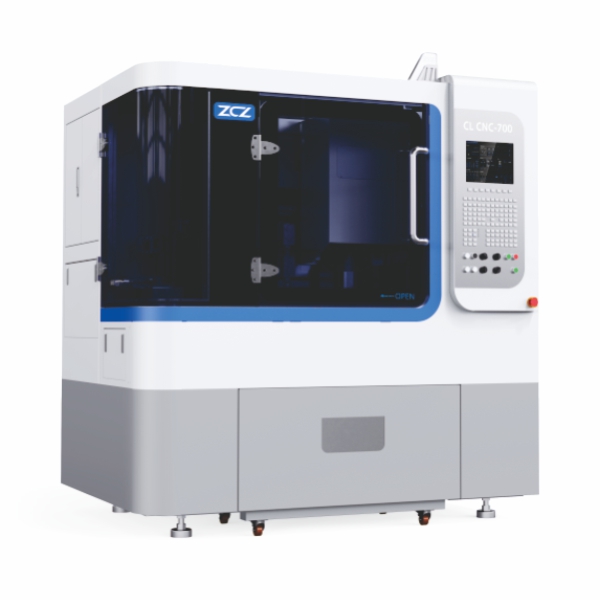

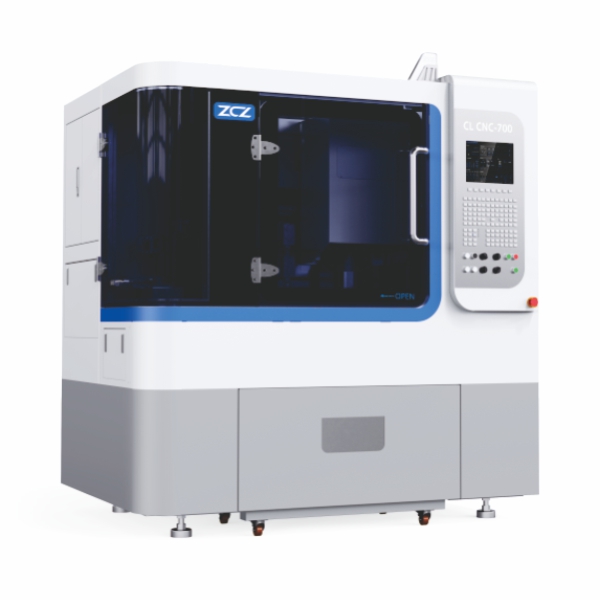

It is installed with 5-axis dual workstation, which is used to process front

frame of rubber frame spectacle, inner ring, outer ring and fancy dual

workstation, one pair finished in one minute, with 10-axis servo driving,

from feeding to processing managed by data, convenient commissioning,

and a processing expert for processing the latest products and quick

shifting of orders.make one pair a minute.

Imported Sanyo 1300W large inertia servo motor with brake with original packaging

10-axial servo driving

Germany Alpha 4-axis and 5-axis divider

Taiwan HIWIN screw and guide rail with original packaging

Specified widened and lengthened chassis

9 Xingchen (Senchen, Huadiao) oil cooling electric spindle Taiwan electric spindle oil cooling unit

Automatic feeding device

Dual work station

Primary molding clamping cradle

Taiwan AirTAC Cylinder

Human-centered discharging bucket

Shortly referred to as “quick”, the only 5-axis, dual-station, multi-axis and complete data memory controlled equipment,high processing rate and quick control

| Performance index | standard value |

| Positional accuracy of X/Y/Z axes movement | 0.015mm |

The accuracy of repetitive positioning of X/Y/Z/A axes | 0.010mm |

| Operating stroke of X/Y/Z axes | 700mm*350mm*250mm |

| A-shaft clamp fourth-axis precision | 0.015mm |

| Table size | 600mm*410mm |

| Spindle power | 1.5KW |

| Ospindle speed | 3000-24000RMP |

| Spindle number | 9 |

| Number of cyclo converter | 2 |

| Shank mode | ER16 |

| Rapid feed rate | 30m/min |

| Working voltage | 220V/Three-phase |

| Driving system | Sanyo alternating current servo |

| Operating system | SYNTEC system +hand box |

| Air pressure | 0.6MPA |

| Machine tool weight | 3000KG |

| Machine dimension | 1900*1600*2200 |

Jion Us ZCL | Yue ICP Bei No.99999999 Copyright 2023 All Rights Reserved By ZCL | 0752 28687538

Pay Attention To Us