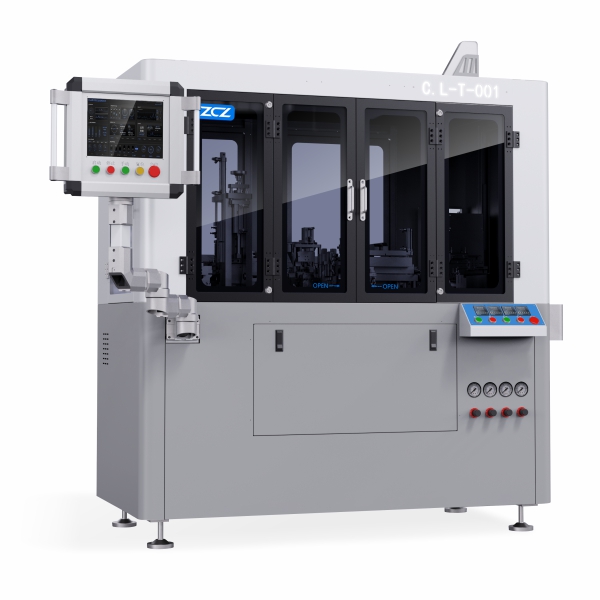

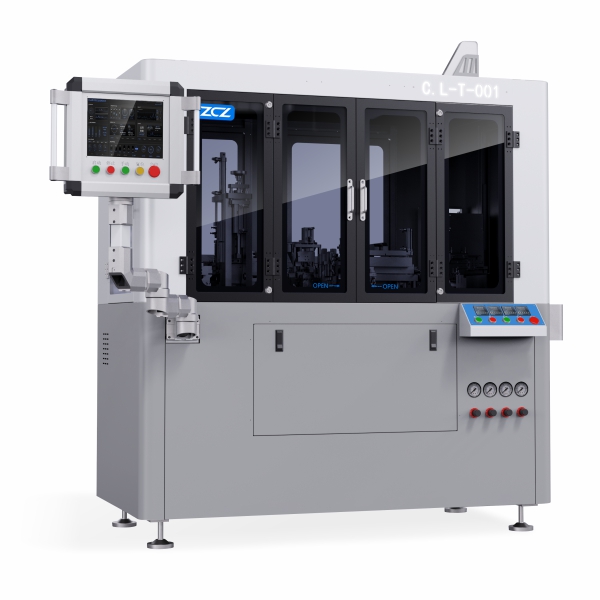

A fully automatic production line, it’s start from surface treatment (entering the acetone), drying the surface, and covering the hinge, surface bending and tail bending, all processes are fully automatic and integrated, completed in one time, one piece take 7~9 seconds, with standardization, saving people and time, and integrating multiple processes. The humanized operating system makes machine adjustment convenient and fast, it takes only 10 minutes for change over new models. It is an ideal choice for intelligent production lines. One person can watch 4-5 machines, and one machine replaces 3 people, which is equivalent to one person doing the work of the original 12 people.

4 processes steps in one.

Reduced time.

Reduced labor.

Fully automatic feeding and blanking changeover.

Improve quality.

Increase production capacity.

And standardize and unify the operation mode.

Jion Us ZCL | Yue ICP Bei No.99999999 Copyright 2023 All Rights Reserved By ZCL | 0752 28687538

Pay Attention To Us