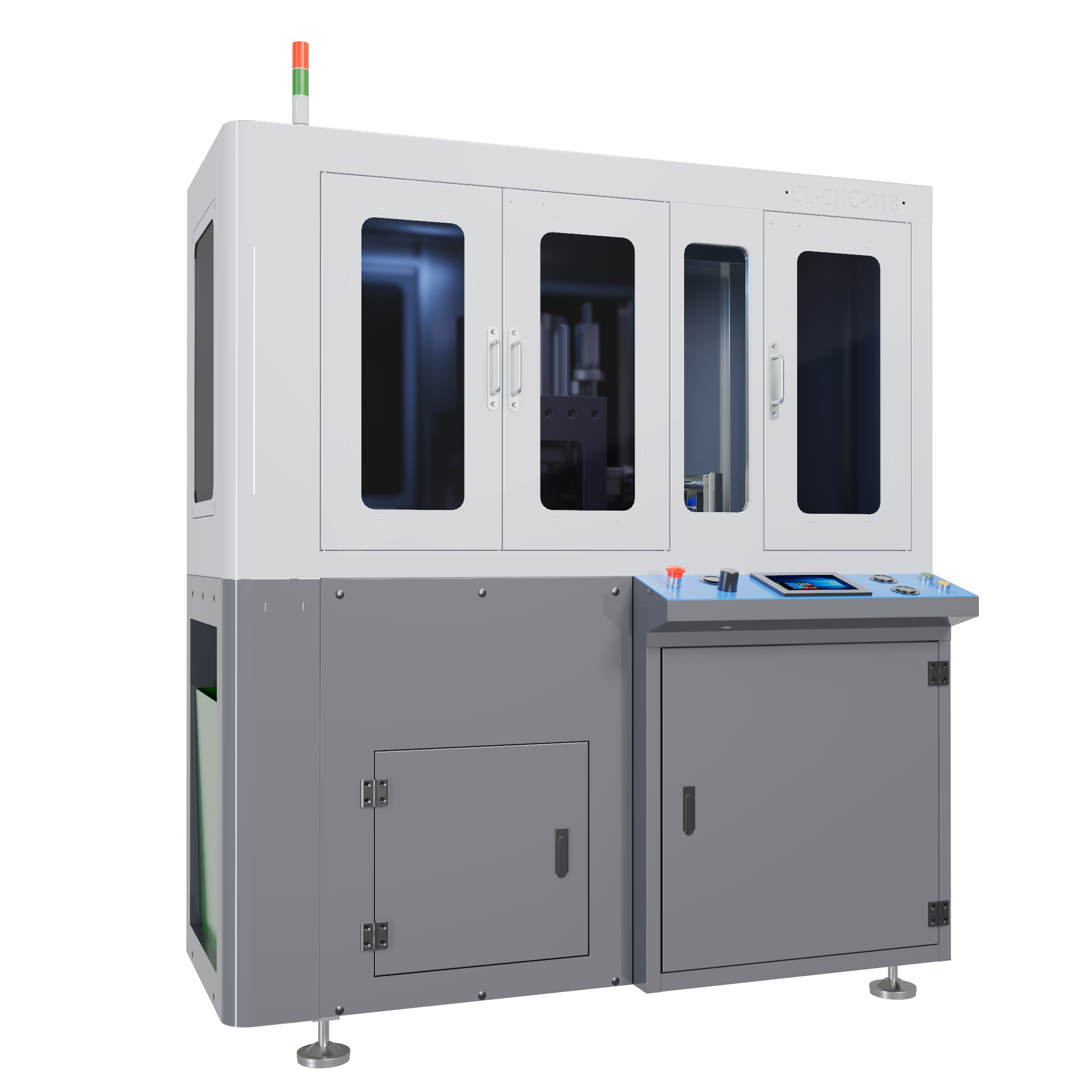

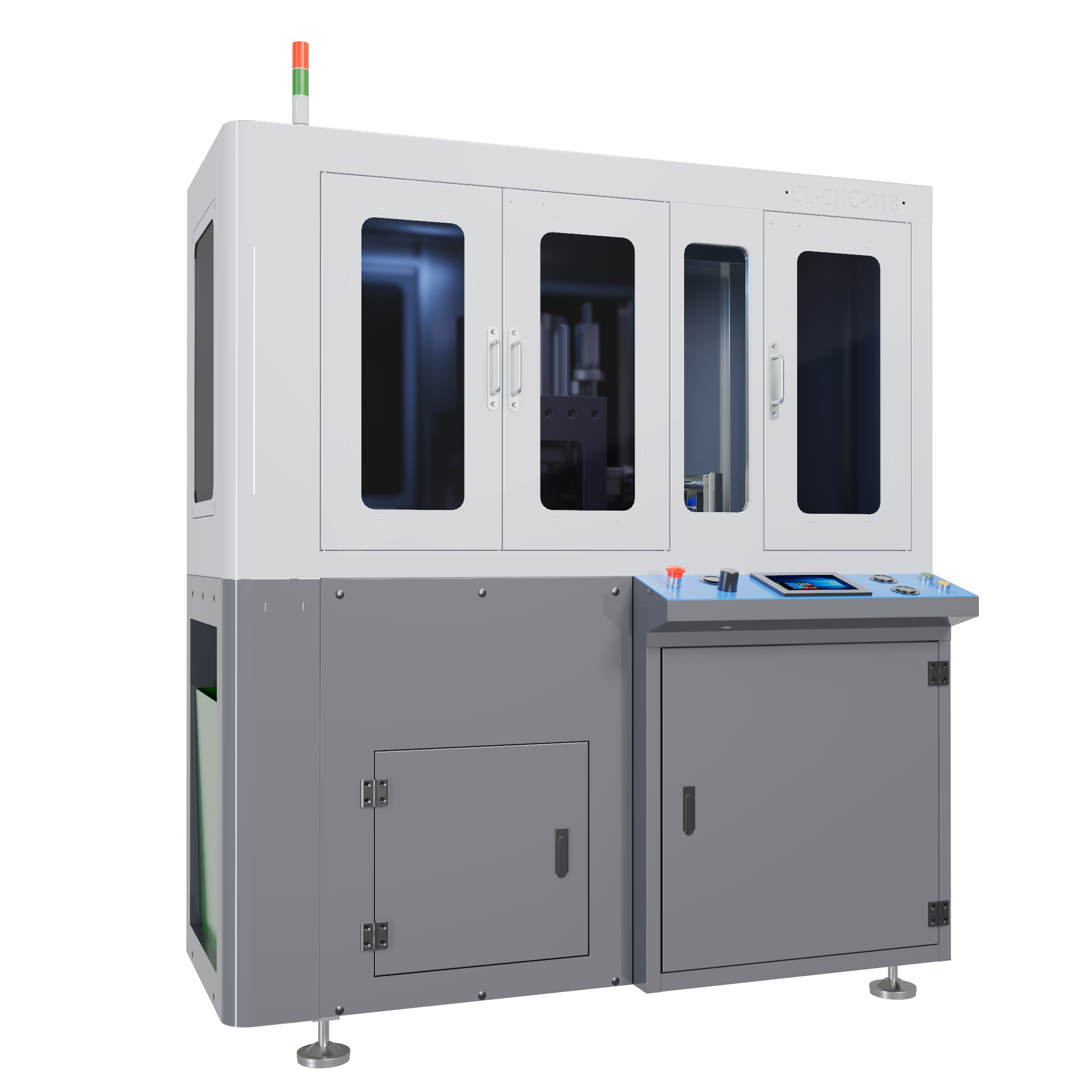

It is designed for the standard working procedure of Acetate frame, and integrates all working procedures including full-automatic loading, bending bridge, end_piece bending, milling of locating slot, full-automatic loading and cooling setting, thus realizing the real automatic production.

Big cylinder body, powerful pressure

Automatic feeding mechanism

Scrap discharge mechanism

Japan SMC and Taiwan SHAKO pneumatic components

Taiwan AirTAC Cylinder

Panasonic vertical motor

Automatic discharging mechanism

It can save labor and working procedure, doesn't need personnel operation, and realize the full-automatic operation.

The center bridge and end piece are stereoscopic and full, the shape is in symmetry, and the middle division is even.

It is equipped with the automatic adjustable heating system, with stable and standard heating.

It is equipped with automatic adjustable cooling system, and cooling setting effect standard is consistent.

| Performance index | standard value |

| Heating system | Mechanical heating |

| Cooling system | Panasonic cooling device |

| Engraving and milling slot power | 250W |

| Spindle power | 550RMP |

| Shank mode | Er16 |

| Working voltage | 20V/50HZ |

| Operating system | PLC man-machine interface |

| Air pressure | 0.6MPA |

| Machine tool weight(KG) | 500KG |

| Machine dimension | 700*1600*1550mm |

Jion Us ZCL | Yue ICP Bei No.99999999 Copyright 2023 All Rights Reserved By ZCL | 0752 28687538

Pay Attention To Us